Why Ezi Klamp GRP Grating is Perfect for Offshore Grating

Offshore environments are some of the harshest working conditions known to man. All materials and equipment must withstand the harshest environmental conditions to help keep workers safe as they work in these extreme environments. One of the most revolutionary materials in this world has been the rise of GRP Grating.

The Dangers of Offshore Environments

There are huge demands on the workers and their working environment. There is a constant battle against the elements, and whilst there has been a vast improvement in the safety equipment and systems used daily, there is always room for continual improvement.

The constant battering that offshore structures take from salt water spray and the wet sea air means that materials must be corrosion resistant whilst remaining low maintenance and safe in wet and windy conditions.

For workers, offshore environments are dangerous places where minor injuries can quickly become dangerous or even life-threatening. Slips, trips or falls on the same level accounted for 23% of all reported offshore accidents in 2021. Most of these meant that workers had to take over three or more days off from work, and with the unique positioning of the work environment, it is not always possible to find a replacement for that role.

For more severe injuries, help may be some time away and be entirely dependent on the weather, so ensuring you have the safest environment possible is essential, and it starts with the materials you use.

What is GRP?

Over recent years, GRP (Glass Reinforced Plastic) has become the premier choice for many industries, including:

- Offshore and Marine Industries

- Construction

- Telecommunications

- Transportation

- Water Treatment

- Electrical and Utility

- Chemical Industries

There are many reasons for this, and it comes down to its unique combination of inherited benefits. For offshore industries, these include:

- Corrosion resistance, especially against saltwater and aggressive chemicals

- Superior strength-to-weight ratio, making it a lightweight yet durable solution

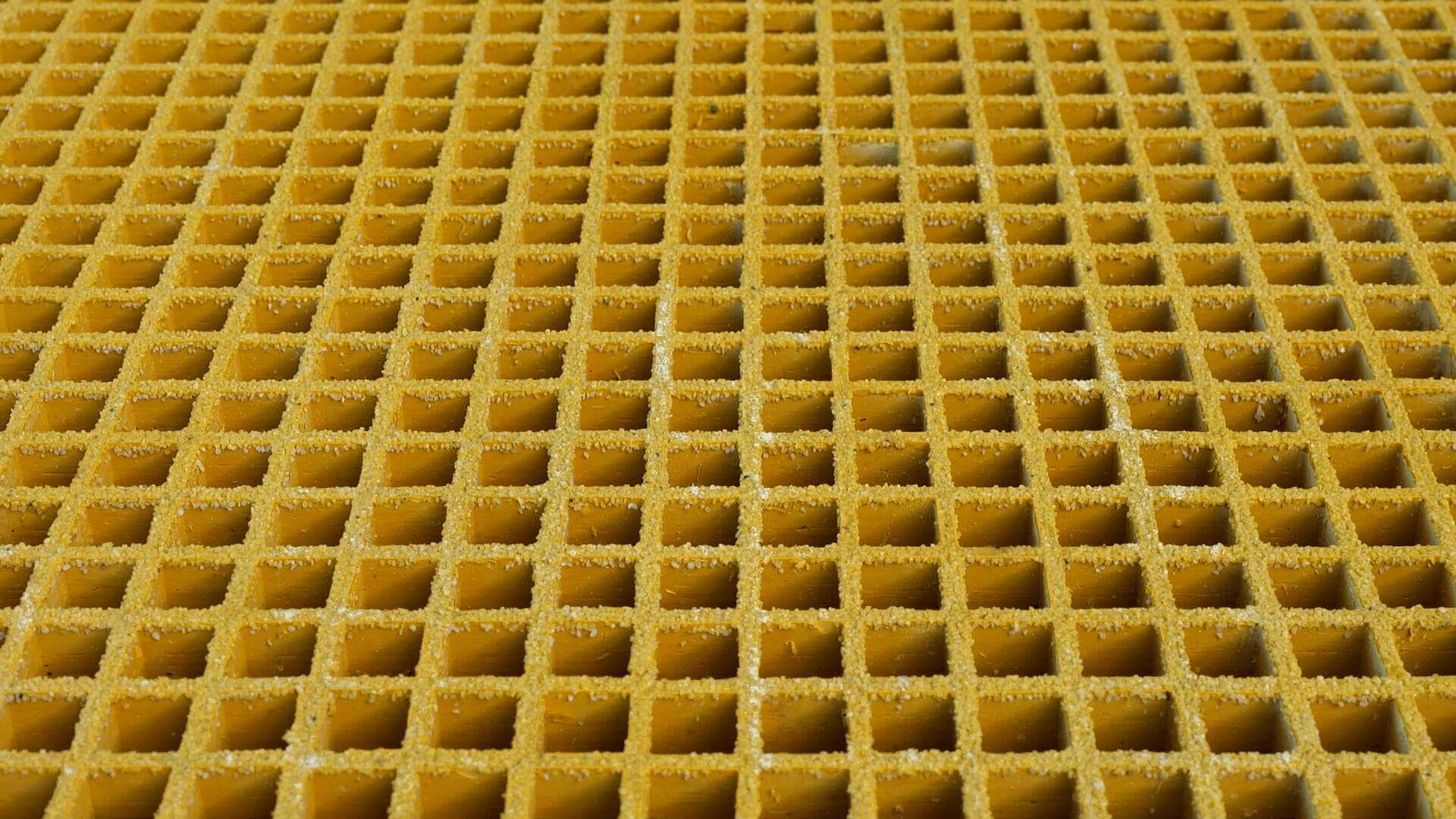

- Non-slip properties ensure safety even in wet or oily conditions

As you can see, GRP has several benefits over traditional materials when it comes to offshore environments.

Where can you use GRP Grating?

With its anti-slip surface and impact-resistant qualities, GRP Grating offers a highly versatile solution for offshore environments, meeting rigorous safety requirements across a range of applications:

Offshore Platforms and Walkways:

GRP grating is an excellent choice for offshore platforms and walkways. Its corrosion resistance and slip-resistant durability ensure safe and stable footing, surpassing traditional steel grating, especially in areas constantly exposed to saltwater and harsh weather.

Drilling Rigs and Oil Platforms:

On drilling rigs and oil platforms, the chemical-resistant and non-conductive mesh GRP grating serves as superior flooring and decking, enhancing industrial flooring safety. Its non-conductive nature ensures safety in electrical environments, and its resistance to corrosion helps maintain structural integrity in corrosive offshore conditions.

Chemical Storage Areas:

In offshore facilities with chemical storage areas, GRP grating is a preferred choice. It resists the corrosive effects of chemicals and ensures a safe working environment for personnel.

Subsea Structures and Submersibles:

GRP grating is usable in subsea environments. The water-resistant and anti-corrosive properties of fibreglass grating make it the material of choice for submersible structures, walkways, and robust equipment support.

Jetty and Pier Construction:

GRP grating can be used for decking and walkways in circumstances where jetties or piers extend into the sea. Its resistance to saltwater and easy installation make it a cost-effective choice for such applications.

Cable Management and Trench Covers:

The open mesh design of GRP grating is perfect for creating efficient cable management systems, and sturdy trench covers on offshore platforms. Its lightweight nature simplifies the installation process and minimises the need for heavy equipment.

Installing and maintaining GRP grating.

Due to its lightweight properties, the installation process of GRP grating saves a considerable amount of time. It can be fitted without heavy lifting gear/cranes or hot work /welding.

With minimal maintenance needs and a lifespan of up to 25 years, GRP outperforms conventional materials in longevity and reliability. In the unlikely event that your GRP grating becomes damaged, replacing the damaged grating is easier due to its lightweight nature. All these benefits contribute to the long-term benefits of using GRP grating over other solutions.

There is more to GRP than Grating

At Ezi Klamp or GRP, the range goes beyond just grating. Our range includes GRP Handrails, secure GRP Palisade Fencing, and durable GRP Step systems, all designed to meet the highest industrial safety standards. We can help you design and supply all of your GRP needs, whether you are looking for secure solutions or just providing a safer environment for your team.

Speak to our expert team to discuss your project and find out how Ezi Klamp can make your site safer for everyone, regardless of location.